Information & Instructions

Review the sections below for important information on product instilation and helpful hints. Before you jump into your transmission, get helpful insights and practical information designed to make your build a smooth one.

Subarugears Transmission Assembly Instructions

Diy 5mt Builddiy 5mt Build

2WD High Power Pinion

!!!Checking Your Axle Length Is Requierd For All Installations Prior To Operation!!!

Axle length verification procedure:

Step #1: Put chalk inside the CV conversion flange when first assembled.

Step #2: Place vehicle on hoist, fit the CV’s and axles on to chassis.

Step #3: Place vehicle suspension at full droop (trailing arm at its lowest point) – and turn the CV and axle assembly.

Step #4: Place vehicle suspension with the axle’s level and turn the axle and CV assembly.

Step #5: place vehicle suspension at full bump (trailing arm at highest point) – turn the CV and axle assembly.

Step #6: Take the inner CV out and see if any of the chalk has been taken off by the rotating assembly.

Removal of chalk from the inner CV conversion flange during rotation of axle assembly is signs of contact and can cause premature failure of the transmission and/or transmission components. Adjustments must be made accordingly.

Signs of wear/damage to conversion flange will void the warranty!!!

Case Modifications

Clearance for the differential carrier, crown wheel, and crown wheel bolts should be checked by progressively fitting each part to the right-side case. Its finished appearance should be similar to the left-side case when complete.

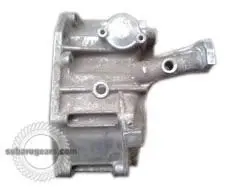

Subarugears machined case

Customer hand ground and finished case

If you’re using the transmission in its 4WD state, that is the extent of your case modifications—move on to fitting the Subarugesars, ring, pinion, and differential setup.

Watch this Subarugesars video for more case clearance information.

Shortening The Awd Case To A 2wd Case For Beetles, Kombis, And Vanagons

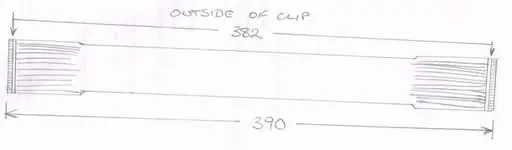

As we are only using the 2WD part of the transmission, the casing can be shortened to 565 mm in length (plus 80 mm length of shifter support tube that is placed over the top of the torsion bar). This should be performed on the later-style center differential housings from 1999 onwards (4-bolt or TY754/755/758).

Earlier style center housings (4-bolt TY752) are difficult to shorten effectively. These are identified by their square panel on top of the center differential case. Newer center differential casings are interchangeable with older-style casings.

Alternatively, you can purchase our Subanose—a one-piece cast nosecone compatible with all 5-speed Subarugesars transmissions. No need to use a grinder or TIG weld; simply transfer the parts from your donor center differential housing and bolt it all on. The shape has been optimized to give the shortest possible shifter support length and maximum clearances.

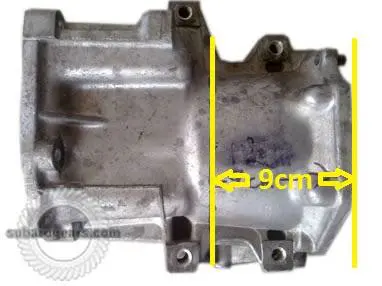

Mark The Cut-Out Line

9 cm (3 1/2 inches) from the end with the cast bosses for the mounts. Do not mark all the way around—leave the base of the shift rod support tube unmarked and uncut. Carefully mark above and below the shift rod support tube. The castings are thin there and are easy to cut through.

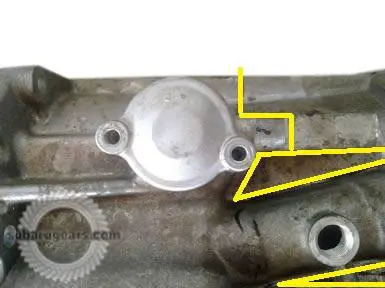

Be very careful—there is a bolt just to the right of this round plate (gearshift interlock) that holds a ball and spring in place. Do not grind off the bolt. Do not grind down the flat mounting surface for this bolt, or the tension that the ball and spring place on the interlock will be incorrect.

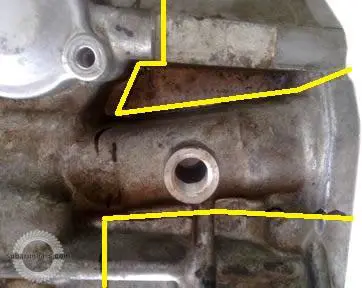

Note there are three holes to fill:

- Large hole with Subaplug.

- Hole on inside of shifter support shaft, filled with TIG weld, threaded plug, Devcon, or Silicon.

- Weird-shaped hole on right-hand side, filled with TIG weld, Devcon, or Silicon.

After some finish grinding and flap disc work plus holes filled with Subaplug, threaded plug, TIG weld.

Complete Shortened Subarugesars Transmission Casing

The casing needs to be welded in three areas :

- On the shift rod support.

- On the outside of the threaded hole that holds the oil splash catcher on the inside.

- In the area where the steel Welch plug from casting has been removed.

Watch this Subarugesars video for shortening the casing.

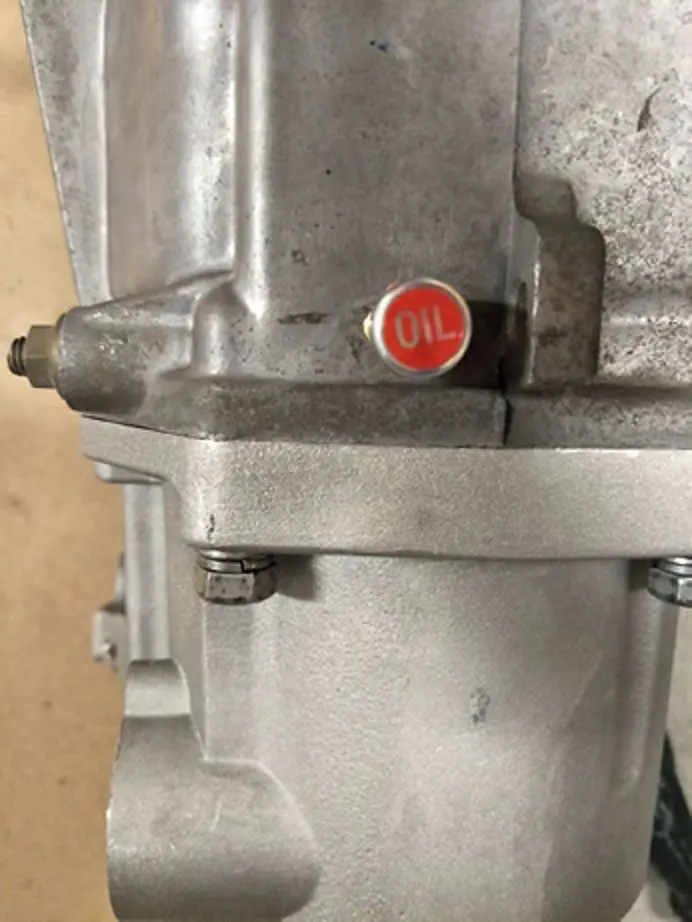

Case Breather

The Subarugesars transmission has a small case breather built into the dipstick. Since the dipstick is no longer able to be used and the dipstick tube is sealed, a case breather should be built into the transmission in order to relieve pressure buildup.

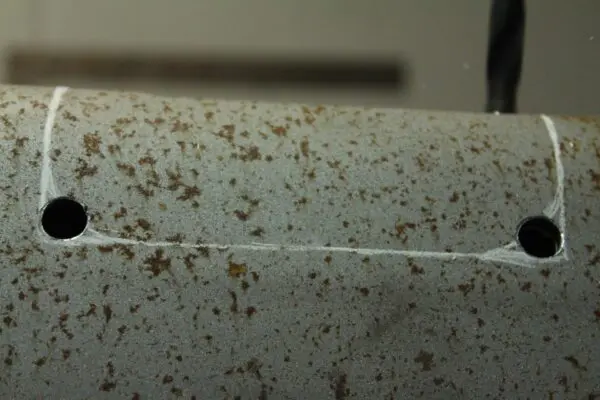

Subarugesars supplies a dipstick cover with each kit. This is a high-temp silicon cover that ensures the oil flung up by the reversed ring gear does not get pumped out of the transmission. In order for the transmission to ‘breathe’ once the oil gets hot and expands/aerates, a breather hole in the casing is required.

The ideal location for the case breather is in the rear of the transmission case, as far out of the way from flinging oil as possible. The suggested case breather consists of one hole just above where the nosecone joins the main case—on the starter motor side. This area is a hollow casting area protected by the horseshoe.

Replacing the Driven Shaft Pinion Gear

1. Prepare

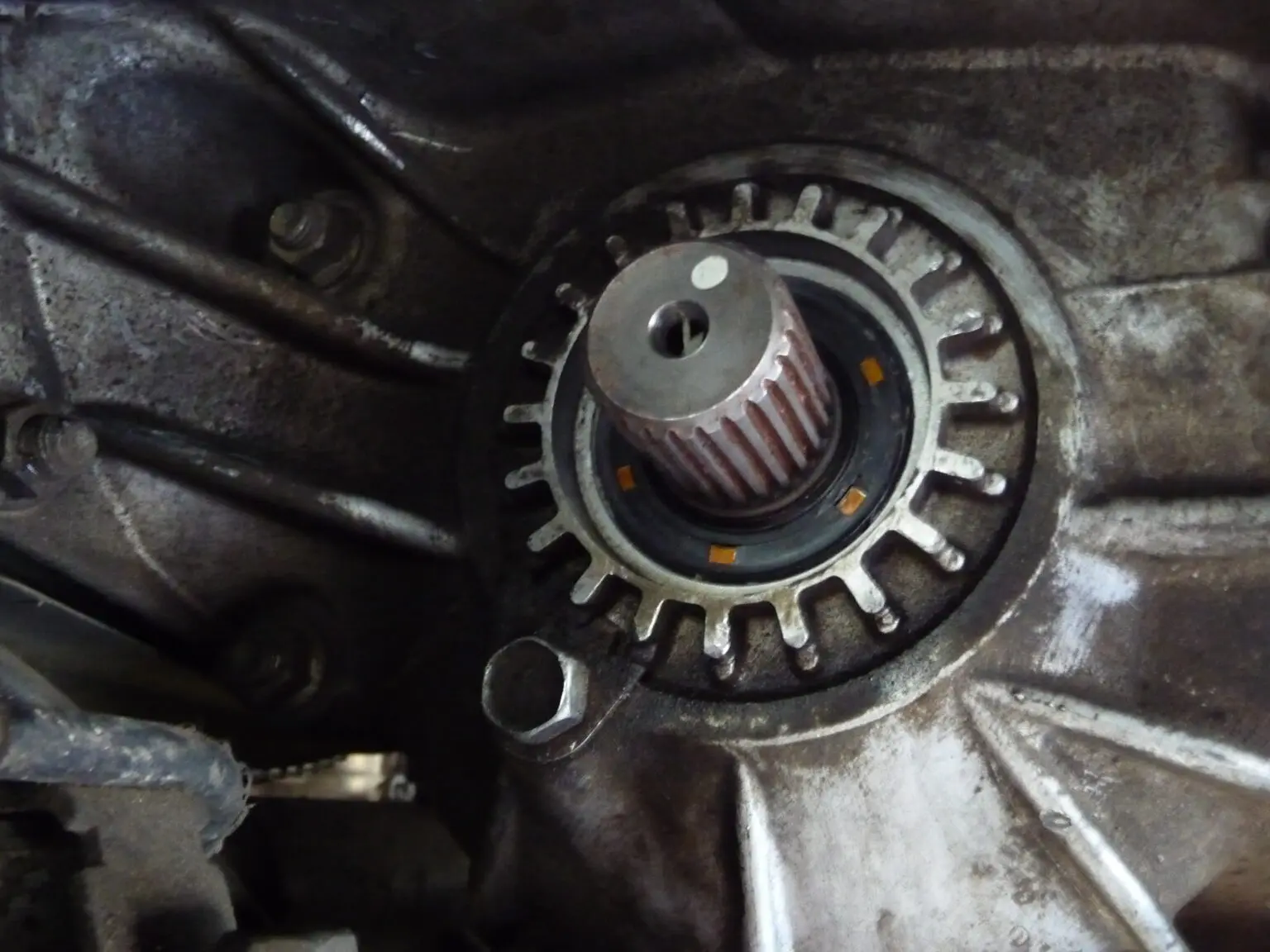

Here is the driven shaft after being pulled from the trans case.

On a front-drive Subaru, or any other front-drive longitudinal transaxle, the gears would be mounted directly to the pinion shaft. This Subaru setup uses a concentric shaft layout and sends a slender front driveshaft through a hollow driven shaft to drive the front differential.

This shaft has the pinion gear on the end of it and is the one that will be replaced.

After the 27 mm retaining nut, some washers, and a bearing are removed from the end of the shaft, pull it out.

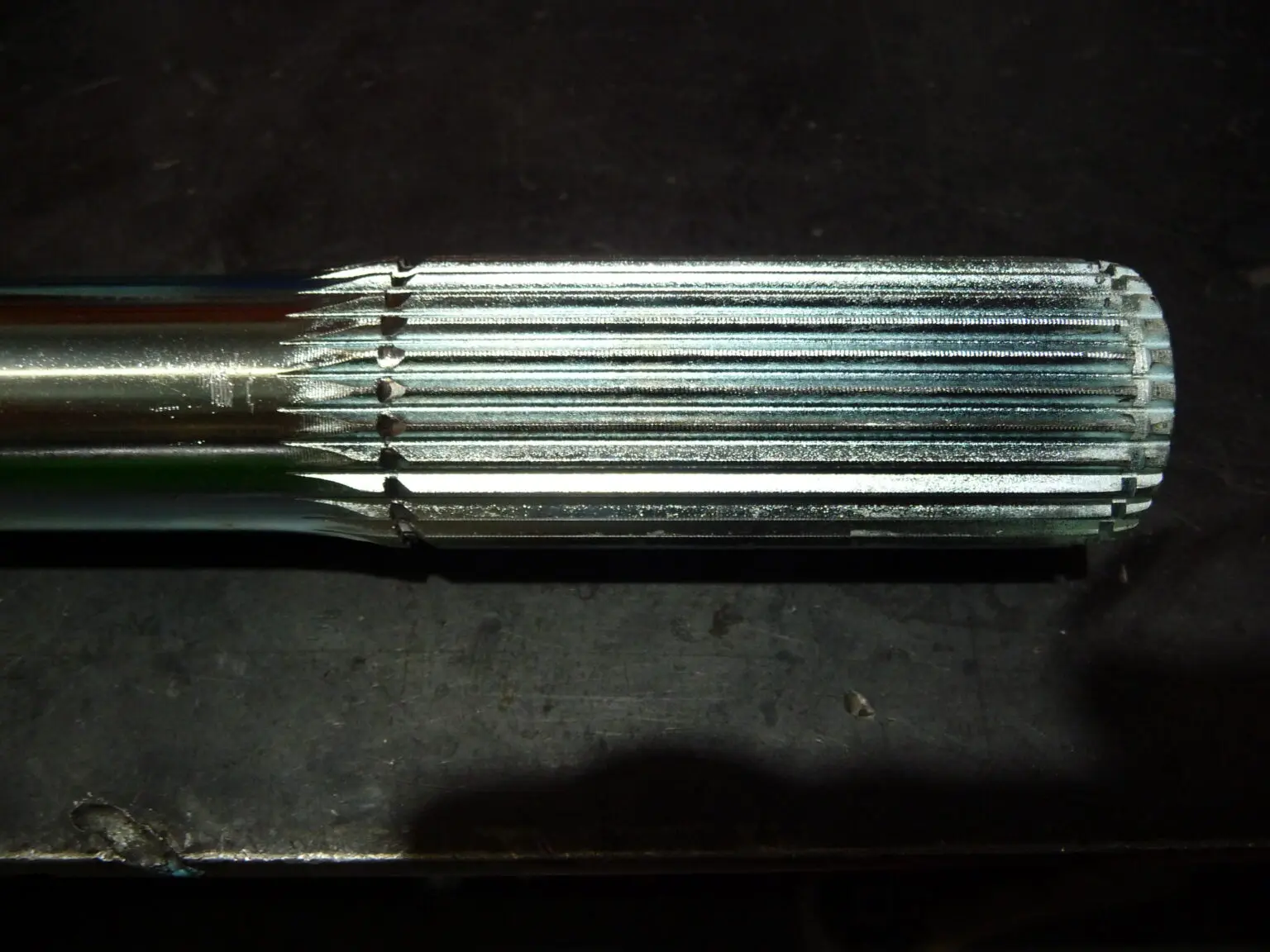

Comparison shot between standard pinion shaft and reversed pinion shaft—note the reversed gear cut on the top one.

The main bearing that the driven shaft rotates on is mounted to the pinion shaft. If your bearing shows no signs of wear, you can reuse it.

The bearing itself is not a press-fit; the collar that holds it on is. The main bearing does not run on its own internal race; it runs directly on the shaft.

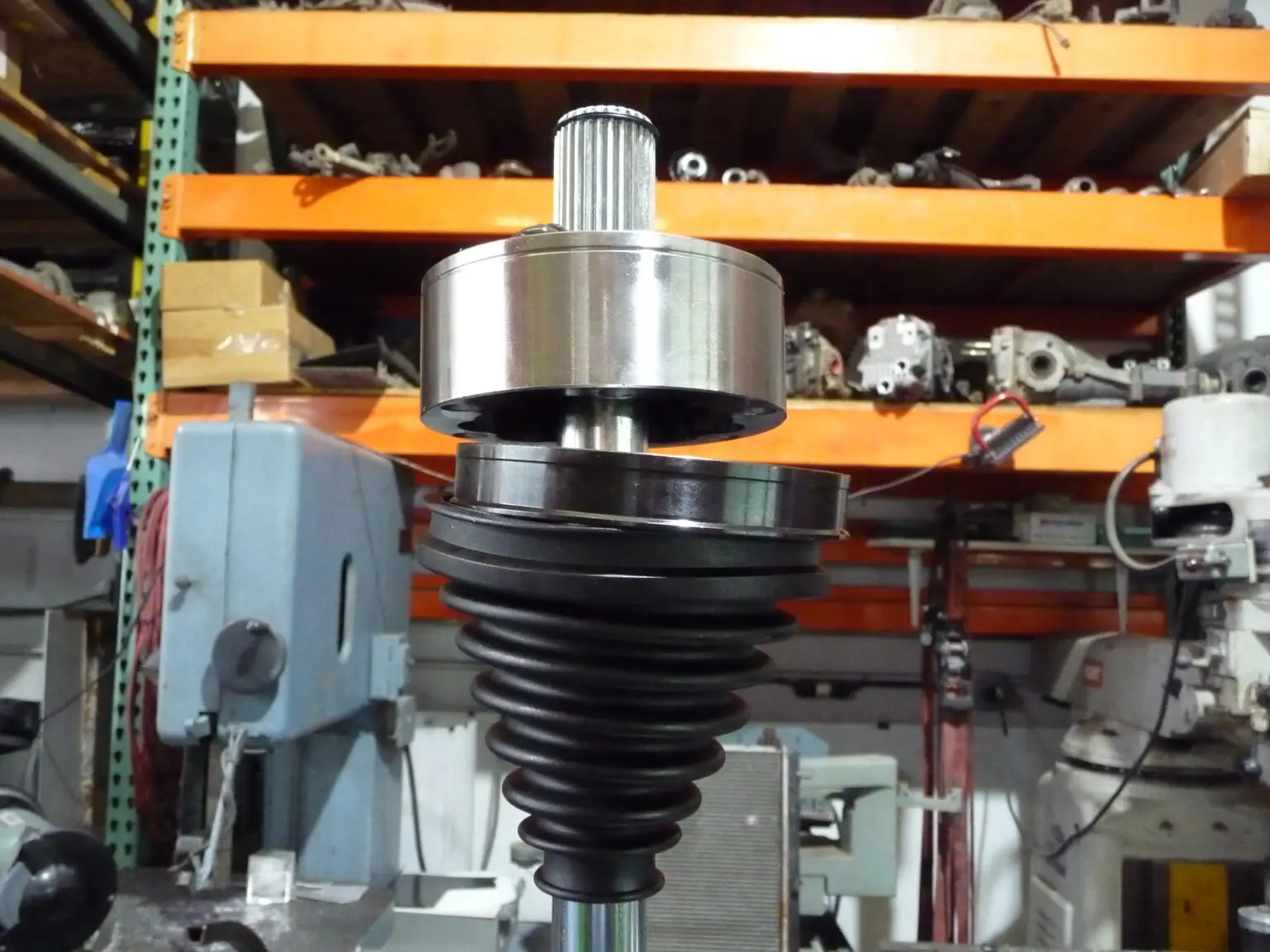

2. Install The Collar

Installation of the collar can be done with an arbor and press. This shows a quick arbor made from aluminum pipe. With the main bearing and collar in place, reinstall the smaller surface bearing that allows the vertical surfaces to move against each other.

For 2WD applications, install the Subaspool in place of the splined adaptor, 2 x washers & 1 x surface bearing at the rear of the pinion shaft.

Completed 2WD assembly with Subaspool installed, 27 mm retaining nut torque, and peened over.

Before reassembling, you will need to swap the stub axle seals over from left to right. The factory stub axle seals are designed as a one-way seal to effectively keep oil inside the transmission case. You can see this in the image below with the diagonal ribs.

Failing to swap these over will cause the seals to ‘push’ oil out of the transmission case. You can either screw out the bearing cups with seals intact, screwing them back into the other side, or carefully pry the seals out of the cups and install them on the opposite side.

3. If You Have The Subaru Factory Tool Available, Set The Pinion Depth

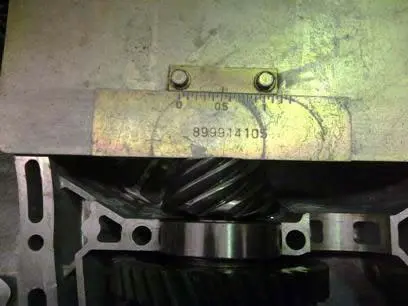

Fit the driven gear assembly to the right-hand (modified) gearbox casing and torque the retaining plate up. Zero the pinion depth gauge on a flat surface (such as glass) by loosening the gauge screws and sliding the wedge in between the flat surface and gauge indicator so that “0.5” lines up with the mark. Tighten the gauge screws. Fit the Subaru factory tool over the gearbox casing with the dowels. Slide the gauge between the end of the crown wheel gear and the plate. This will show you what thickness of shims you require. This picture shows that the reading is 0.5, and thus will need shims with a thickness adding up to 0.5 or just below to bring the pinion depth to zero. A Subarugears Pinion Depth Tool is included in every gear purchase.

Adjust the pinion depth with various shims fitted between the shaft retaining plate and the housing. We re-fitted the two original shims to set the pinion depth to zero.

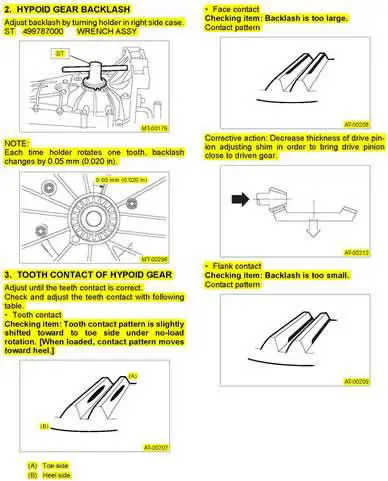

4. Set The Crown Wheel Mesh Into The Pinion Gear

Set the crown wheel mesh into the pinion gear by adjusting. Assemble both halves of the gearbox, with the crown wheel and pinion in place. Screw both side bearing covers in and out as per the factory manual. The pinion shaft should turn easily with a tiny amount of slack when engaging the gears. Once you have met factory specifications, you need to double-check the gear mesh with a physical test.

5. Disassemble, Assemble, Disassemble

Disassemble the case again and smear bearing blue or yellow gear-marking grease onto all surfaces of the pinion bearing. Smear blue onto four teeth on each quarter of the crown wheel gear. Assemble the gearbox again and turn the pinion shaft a number of full rotations in both directions.

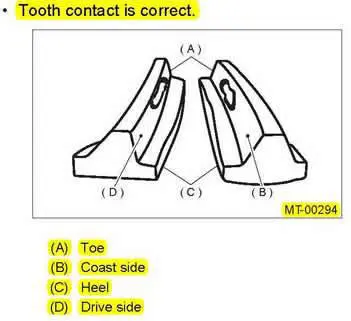

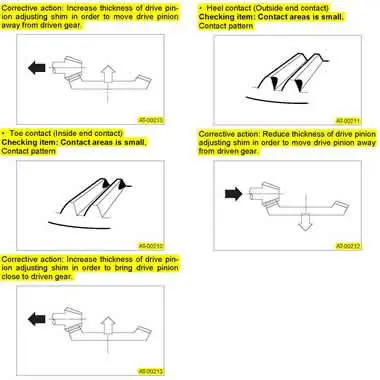

Carefully disassemble the case again and inspect the meshing patterns of the gears, using the factory specifications and illustrations as your guide. Make adjustments as necessary.

6. Check The Meshing Pattern

The meshing pattern on each gear should slide along the majority of the gear, engaging and disengaging before the ends where the teeth are weaker. Ensure the depth of gear mesh uses the majority of the tooth but doesn’t bottom out.

Clutch Setup

The standard cable clutch and Bowden tube can be used with the Subaru transmission. It’s recommended that you use the cable clutch fork from Subaru's own cable clutch transmissions. This clutch fork is longer and is designed to have a cable slotted through it. The pivot point is changed by moving the mushroom pivot bolt in the transmission bellhousing to the alternative threaded boss already provided.

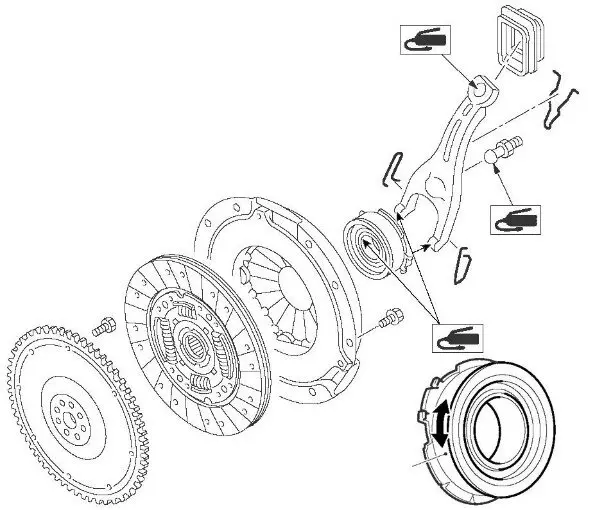

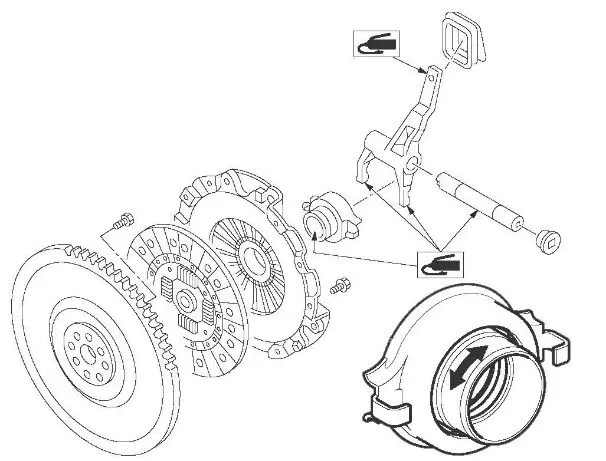

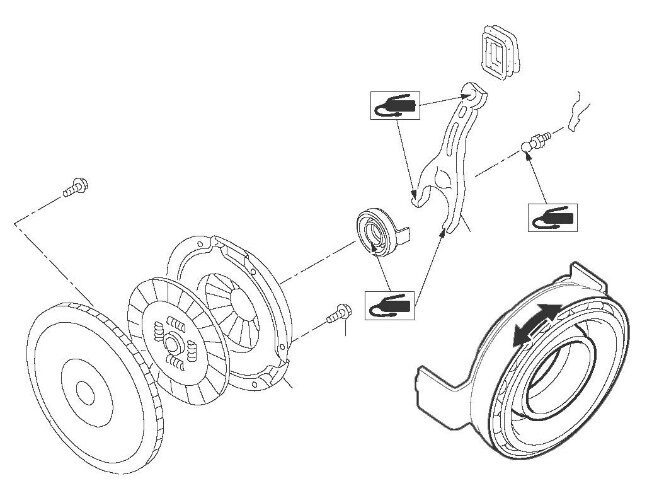

Our preference is to install a hydraulic clutch system. The Subaru transmissions have a slave cylinder bolted to the top of the transmission. There are two types of transmissions with their matching flywheels, clutches, and master/slave cylinders: push type and pull type.

Non-turbo push clutch

Turbo pull clutch

Turbo push clutch

Subashifter Install Instructions Video

Shift Rod Connection

This can be manufactured from the Subaru shifter knuckle, one knuckle ground down to 45 degrees to allow movement past horizontal. Weld a threaded rod to the knuckle and weld a wheel stud to your shortened VW shift rod.

For a Complete List Of Subaru Awd Models, Download The Pdf From Rallispec Here Or Get Started With Your Calculations.

Typical Gear ratios

Transmission

1st / 2nd / 3rd / 4th / 5th / 6th

5MT Turbo

3.16 / 1.88 / 1.30 / 0.97 / 0.74

5MT non Turbo

3.45 / 2.06 / 1.45 / 1.09 / 0.78

6MT turbo

3.45 / 1.94 / 1.30 / 0.97 / 0/78 0.67

6MT non Turbo

3.45 / 1.94 / 1.30 / 0.97 / 0.82 / 0.69

6MT Tdi turbo diesel

3.45 / 1.75 / 1.06 / 0.79 / 0.63 / 0.56

4EAT TZ1A / TZ1B 4 speed automatic

2.78 / 1.55 / 1.00 / 0.69

Use the Calculator to Make Your Life Easier.

Gear Ratio Rpm To Mph Calculator With Auto Shift And Tracer

Calculator Steps

1) Enter gear ratios into the table below. Select 4 gears (VW), 5 gears or 6 gears to compare transmissions

2) Enter the tyre diameter in inches

3) Enter the Diff Ratio.

4) Finally, enter the RPM you would shift at. Click on shift and trace.

How to Measure IRS Axle Length:

1.) First adjust your rear wheel alignment toe in. If your tires are toed out like a duck your trailing arms will be closer to your transmission resulting in a shorter axle.

2.) Lift the trailing arm so that if you did have an axle it would be parallel to the floor at zero degrees. This is your shortest point.

3.) Measure from the center of the drive flange on your transmission to the center of the stub axle on your trailing arm. DO NOT measure where your CV joint mounting surface is. You need to measure the bottom of each cup because this is where your axle will plunge into. If you purchase too long of an axle, when your trailing arm moves upward to zero degrees it will shove the axle into the transmission. This will mushroom the ends of your axles and eventually crush the ring gear inside your transmission.

4.) After you have measured this distance, you subtract 1/4 inch total length. For instance if you measure from the center of the drive flange to the center of the stub axle and you get 20 1/2 inches you would buy a 20 1/4 axle.

5.) Measure both sides of the car. It is NORMAL to have unequal length axles.

Axles & CV Joint Options

Option 1, remove frame horns, then standard Bay window cv joints and axles will bolt up.

Option 2, scalloped frame horns and extended length Subaflanges, then shorter axles will need to be ordered from Sway-away in the USA, or have a local supplier cut your Bay Kombi axles down to length and respline them. DO NOT ‘cut and shut’ re-weld axles as they will break and/or cause damage to ring and pinion quickly if they are out of balance.

How to measure, test, and assemble

- Place vehicle on 4 jack stands so all wheels can rotate freely.

- Remove front wheels.

- Remove front axle nuts.

- Push axles in towards center of vehicle through hub.

- Remove both front struts complete while supporting hubs. We hang them with straps.

- Remove the spring, bump stop, and covering from one of the struts. Be sure to use a spring compressor.The spring is under tension and can cause severe injury. This strut will be used to measure both sides of the vehicle. Re-install top hat and tighten nut.

- Install this strut back on the original side it came off of.

- Remove both sway bar end links in order to cycle each side separately.

- Transmissions that have stub ends in them jump to step 13

- Remove axle seal from transmission and replace with new provided seals. These seals are side specific. There is an R and L can be found on the seal surface. Driver side is Left. Some models require removing the bearing adjuster. Make sure you mark the original position and only do 1 side at a time. These caps are very important to the ring and pinion and should be put back the exact way they came out. Make sure not to damage the o-ring or sealing surface. Apply oil to o-ring before reinstalling it. See shop

manual if you are unsure on how to replace these seals.

- Install this strut back on the original side it came off of.

- Remove both sway bar end links in order to cycle each side separately.

- Transmissions that have stub ends in them jump to step 13

- Remove axle seal from transmission and replace with new provided seals. These seals are side specific. There is an R and L can be found on the seal surface. Driver side is Left. Some models require removing the bearing adjuster. Make sure you mark the original position and only do 1 side at a time. These caps are very important to the ring and pinion and should be put back the exact way they came out. Make sure not to damage the o-ring or sealing surface. Apply oil to o-ring before reinstalling it. See shop manual if you are unsure on how to replace these seals.

- With the suspension at full droop (suspension dropped all the way down) measure the distance from the groove in the outer CV to the inner shaft inside the flange on the side where the strut was reinstalled.

- Record the distance between these 2 points

- Jack up the hub until the strut bottoms out at full bump. Measure distance again and record the measurement.

- Take the shortest measurement between the 2 and add 1/2” to the measurement. This is the length for the axle shaft needed.

- Remove strut and install on opposite side. Repeat steps 15-18. Measurements may be different.

- New axles may be marked R and L on the ends. Be sure to use correct sides.

- On the inner spline there needs to be a second snap ring groove made at the end of the splines before it tapers off. This groove should be approximately the same width of the existing groove at the end of the shaft.

- If the shaft needs to be cut to proper length, cut off the other end to proper length and taper the splines to aid in install.

- 1” from tapered end there needs to be another groove cut into the splines, .100” wide. Verify groove is wide enough for the snap ring.

- Assemble axle dry (without grease) and install on side with bare strut installed. Tighten outer axle nut and install 2 bolts to mount inner CV assembly to flange.

25. At full droop verify axle does not bind (there should be little play on the shaft) and turn from lock to lock while rechecking for axle shaft binding.

26. Jack up hub to full bump and turn lock to lock while verifying axle shaft never binds or gets tight.

- Repeat steps 25 and 26 on opposite side. Move strut to other side and install dry assembled axle for correct side.If any binding occurs on either side then the axle length must be shortened until binding stops. Only take off ¼” at a time from the non-tapered side. Each time a new groove must be added to reinstall the snap ring. Reinstall and re-test until there is no more binding.

- Remove both axles and reassemble with grease, boots, and clamps.

- Remove outer CV joint and fill with grease until it pushes past the balls.

- Install shaft until it clips in the snap ring. This should push more grease past the balls.

Rotate shaft in a circular motion mixing grease into balls and cage. Once grease is mixed in adequately, add some more grease to the top of the cage and balls around the shaft. - Slide outer boot down shaft.

Remove any grease in boot mounting surface and install boot.

Install both clamps.

Make sure not to over tighten clamps, this will cause premature failure of the boot. When the clamp is tight the boot will no longer spin on the joint or shaft.

32. Slide inner clamp and inner boot down the shaft to leave room for assembly.

33. Install one snap ring on inner most groove.

34. Grease inner CV assembly so all mating surfaced are coated. Install boot ring and CV assembly with the small cage opening of the CV towards end of shaft.

- At this point the axle can be bolted into place… or you can remove the inner flange from the vehicle and completely build the axle off the vehicle.

This seems to be the easier way.

Make sure the cv bolts get torque to 50lbs. You can re-torque after 500 miles. New bolts will stretch a bit at first.

- Once shafts are built the vehicle can be reassembled and with loaded struts. Don’t forget to reattach the sway bar (if you plan on keeping it).

- Install the axles and make sure the boots and clamps clear by 1/4” all the way around.

Torque the axle nut to factory specifications. ( re-torque after 100 miles) - Road test and enjoy!

These CVs are meant to last which means you will have to remove, inspect and re-grease them

occasionally. We recommend doing this every year if you abuse your vehicle like we do!!

Please remember this is an off road part, different than factory specifications.

The balls, cage, and star can be replaced if any scaring is found during service. We recommend buying a spare inner and a spare outer set of internals along with 1 inner and 1 outer boot with clamps.

We carry spares in our vehicle for long trips so they can be rebuilt on the road without

delay should it be necessary.

If you have any questions please call RFC Industries at (951) 691-5679.